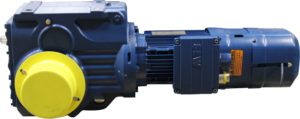

The Motor

Affects: Speed, Torque, Braking, Power Consumption

Options: Single and Two Speed, RPM and Torque values

Description: Key distinctions in motors can be found in two vs. single speed and varying RPM and torque capabilities. Motion manufactures rotary indexing tables with low-friction internal components; it is common for a Motion rotary indexer to require a considerably smaller, more efficient and cost effective motor than leading competitors.

Safety Standards

Affects: How quickly a fully loaded rotary indexer can safely be brought to a full stop, visibility

Options: Motion addresses this issue in table and motor sizing. Other indexer-related safety options include light screens, emergency stop buttons, colors and various others.

Description: Safety standards vary widely from company to company and even more from country to country. Safety is one of the most heavily regulated factors in most industrial processes and many technologies are available to meet these standards. Motion does not provide safety fixtures outside of those directly related to the indexing drive such as light screens or rubber mats. Solutions provided by Motion typically call for motors with enough braking power to bring a fully loaded rotary indexer to a complete stop within a set time, as well as an indexer designed to withstand multiple e-stops without degradation of performance.

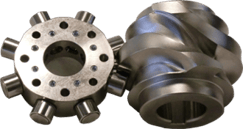

The Cam

Affects: Station Count, Indexing Speed, Longevity, Precision, Strength

Options: Barrel, Globoidal, Disc Various Laws of Motion, Physical Dimensions

Description: The heart of an rotary indexer is its cam. It directly drives the dial plate/output shaft via the mechanical interaction between cam and cam followers (fixed to output). The rotary indexer’s precision is entirely dependent on the quality of the cam’s surfaces; high-precision machining is necessary for the cam’s surface(s) to ensure an accurate dwell. The longevity of an indexer is first addressed at the hardening process of the cam and cam followers, which creates wear resistance and resilience to unnatural impacts (such as e-stops). Station count and indexing speed are both determined by the cam’s physical qualities.*

* Note that the Motion Flex line of servo-powered flexible indexers do not have a physically determined dwell, acceleration or deceleration. These constant lead cams are different from those used in fix indexers.

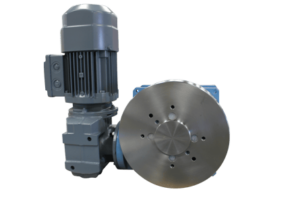

The Dial Plate

Affects: Applicable Tooling Configurations, Precision at Tooling Interface Points

Options: Custom Dimensions, Hole Configurations, Surfaces, Material.

Description: The dial plate (aka indexing head) is the part of the rotary indexer most processes interact with. It is a mounting surface fixed to the indexer’s top dial with machined holes at various points for tooling. Whether you are mounting large sets of robotic welding equipment or fine fixtures to hold toothbrushes while bristles are inserted, the dial plate is where it is all attached. Dial plates and structural frames can come in almost any shape and size provided it is physically possible for the table to handle it.

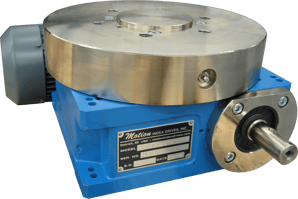

Surfaces/Coatings

Affects: Air Quality (via VOCs and surface exposure), Corrosion Resistance, Visibility, Range of items that can contact surface

Options: Various Colors, Low VOC and Water-Based Paints, Nickel Plating

Description: A Rotary Indexing Table’s surface impacts several items of concern for safety, environmental and production. Visibility of heavy machinery such as an indexer is of importance for relevant safety standards. Low VOC paints may also be required for certain air quality standards or LEED facilities. Additionally, the surface coating is a rotary indexing tables first line of protection against corrosion, which is a common issue – many indexers Motion has serviced have been found in up to a foot of standing water, oils and other various fluids. Nickel plating is the standard solution for many clean room indexer applications because of its reliable resistance to corrosion.

Stainless Steel Plated RT100 Rotary Index Table

RT160 Sealed Rotary Index Table

Oil

Affects: Flammability, Longevity, Accuracy

Options: Oils vary as widely as the plant and wildlife Earth has to offer

Description: Motion Index Drives, Inc. recently placed rotary indexers for fire door operation in a facility that handles weapons grade radioactive materials. As you can imagine, the oil placed in the indexer had to be particularly non-flammable and resistant to high radiation levels. Although extremely costly, this oil serves as an example of how widely the chemical properties of oil can vary. More commonly, oils that can be safely exposed in environments that perform food process or medical manufacturing tasks serve as an example of non-standard oils. Motion completely immerses the internal components of its indexers in an oil bath; many models will never require an oil change.

Learn more information on how Motion Index Drives can customize your Rotary Table application or view our Guide on Rotary Index Tables.