Introduction to Rotary Index Tables

Rotary Index Tables have many applications in manufacturing including machining, assembly, inspection and welding. Indexing tables are positioning devices used to index parts in angular increments to be machined or assembled. They are application specific and are designed and manufactured to meet the needs of a specific operation or set of operations.

All of our rotary indexers are cam driven. On small tables you have the choice of either a worm gear motor or helical bevel gear motor. Larger rotary index tables, a helical beven gear motor is most commonly used.

Selecting a Rotary Index Table

There are important factors to consider when selecting a rotary index table. In principle, it may seem relatively simple to rotate a component and stop periodically at precise angles. In practice however, it can become a surprisingly difficult challenge to design and build machines that will do this precisely and reliably over the lifespan expected of modern manufacturing machinery.

When selecting a rotary index table then, it’s important to be able to specify the following:

- – Accuracy

- – Backlash

- – Mass Moment of Inertia

- – Acceleration and Deceleration

- – Speed

- – Environment

To learn more about specifying a rotary table, you can get our guide here.

Types of Cam Indexers and Applications

Servo Driven Gear Head vs. Programmable Index Drives for Horizontal Rotary Index Table Applications

To understand when you should be considering a cam indexer instead,

read about the differences here.

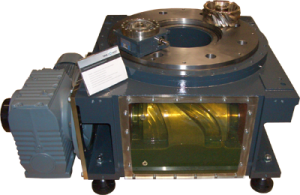

Servo Driven Barrel-Cam Rotary Index Table

With a servo-driven barrel cam rotary index table, it’s possible to deliver a wide range of table sizes, with zero backlash and unparalleled accuracy. Servo driven rotary indexers allow heavy inertial loads to be rotated in a very smooth and controlled manner.

Cam-Driven Indexing Rotary Index Table

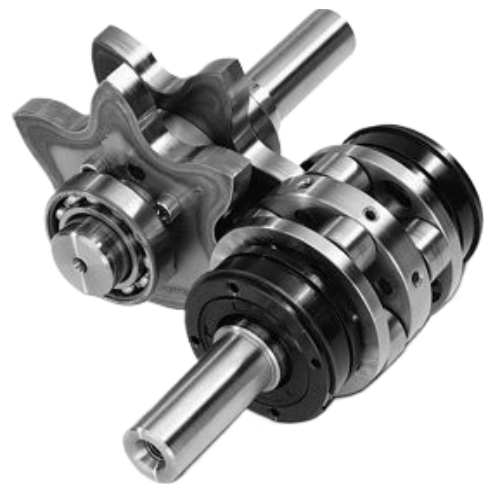

Barrel Cam-Driven Rotary Index Table Drive

Barrel cams represent strength in indexing. Primarily found in rotary index tables, indexers utilizing barrel cams feature the greatest strength /size offering available.

Barrel Cam Rotary Index Table Drive

Flat / Disc Cam-Driven Rotary Index Table Drive

Flat / Disc Rotary Table Drive

Globoidal Cam-Driven Rotary Index Table Drive

Globoidal Rotary Table Drive

Fixed and Flexible Rotary Indexing Tables

Rotary index tables can also be ‘flexible’. Flexible rotary index tables use a cam that has a constant lead, that is the output is at a constant velocity if the motor is running at a constant velocity. Constant lead cams provide a high-precision mechanical transition of power to the output and since acceleration and deceleration are still necessary, the logic controller for the index tables motor provides the necessary control.

Rotary Index Table Machine Components & Options

Common components / accessories that we are asked to provide include:

features

1

Machine Bases

2

Slip Rings / Rotary Unions

3

Top Dials

4

Tooling Frames

5

Controls

6

Robot Integration

7

Custom Coatings

8

Motors and Reducers

9

Trunnion Riser Weldments

10

Mechanical Safety Lockouts

10

Mechanical Safety Lockouts

11

Explosion proof drive systems

For a more in depth review of these components, you can read here

Rotary Index Table Commissioning

Rotary Index Table Maintenance

If you need any technical or service assistance please contact us for 24 hour support.

Selecting a Rotary Index Table Manufacturer

Features that can be important in your rotary index table include:

Low friction internal components. Lower friction index drives can require as little as one-third the amperage to operate while producing greater torque.

Flame-hardened cams and cam followers. Flame-hardened cams and cam followers can withstand forces that cause less robust components to prematurely fail.

It goes without saying that your rotary index drive partner should be ISO 9001 Certified and embrace a culture of continuous improvement. To learn a bit about what we feel makes Motion Index Drives a uniquely valuable rotary index table partner, you can explore here!