Greif, a company who manufactures steel barrel containers, needed a device to smoothly rotate a large 55 gallon steel drum on a pivot torque arm. The device had to have enough torque and smooth acceleration and deceleration as well as lock into position. The customer wanted a cam actuated system to eliminate cost in integrating a drive and the time in making a program to achieve the exact profile and stroke desired.

SOLUTION

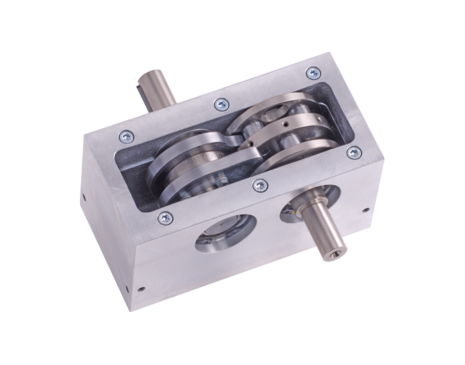

Motion Index Drives model XP250/2/300 was recommended for this application and has been integrated many times for this customers facilities throughout the world. The XP250/2/300 utilizes a flat cam system that had a cam profile of 300 degree index angle and 60 degree of locking dwell period. The 300 degree index angle was able to achieve a very smooth rotation of the 55 gallon drum. The cam was a two station cam that enabled the drum to be perfectly rotated 180 degrees without over turning. By implementing the XP250 cam indexer, the customers integration time was minimize and commission errors were eliminated. Gear driven systems have a much higher cost of integration and commissioning that do cam operated systems with fixed number of stations, such as the 2-station flat cam of the XP250.