An integrator building an automated assembly line for A123 Systems Company producing batteries to operate hybrid and electric vehicles approached Motion Index Drives for a special precision link indexing conveyor. Indexing precision was very critical for the processes occurring in 48 separate stations. The customer also required a system that would not accumulate positioning error during a continuously rotating conveyor in one direction. Linear indexing stroke desired was 24 inches in 1.5 seconds. The customer’s accuracy requirement was 0.020” from one end of the conveyor to the opposite end with the repeat-ability requirement to be +/-0.005”. The total length required was approximately 43 feet. The customer wanted to suspend the fixture and part directly to the conveyor links and with 48 fixtures and parts arrayed at 20 lbs. each the construction of the precision conveyor system needed to be extremely rigid to move 192 links and 48 fixtures.

SOLUTION

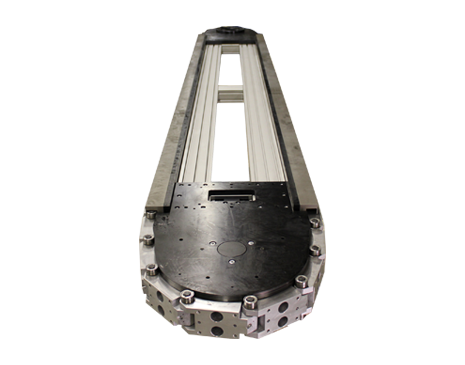

Motion Index Drives LF150-13800 Precision Link Indexing Conveyor was a perfect solution for this application. The LF150-13800 is able to achieve an accuracy of +/- 0.0015” at the front end of the conveyor far exceeding the customer’s requirement of 0.020” of accuracy. At the opposite end over 45 feet from the front end had an accuracy of +/-0.006”. The repeatability we could achieve was +/-0.003” from one end to the other. The index stroke of 600 mm was achieved by stroking (3) 150 mm links at each time. The system was equipped with a RT250-2 two-station barrel cam indexer. By using the RT250-2 barrel cam indexer we could achieve and exact 600 mm stroke on each index. The RT250-2 has a locking dwell which enables the LF150 Precision Link Conveyor to lock in position every 600 mm stroke. On the opposite end of the RT250-2 is a flat polygonal cam plate to take preload the link system as well as allowing for a smooth vibration free rotation of the links as they are rotating. Our LFA/LF conveyors are manufactured to have an exact ratio to eliminate any accumulation error after millions of cycles. The billet aluminum links ride in a hardened and ground track to give accuracy in X, Z and Y axis of +/- 0.001”. Each link has 10 cam followers riding in the hardened and ground track giving each link extreme rigidity to handle unsupported hanging fixtures.