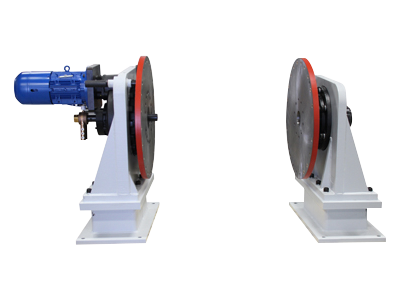

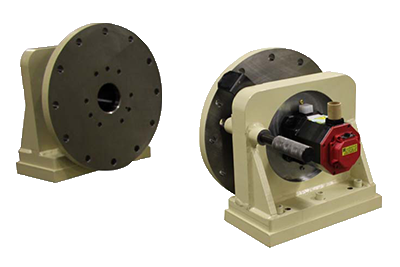

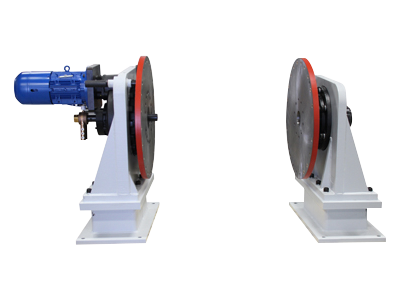

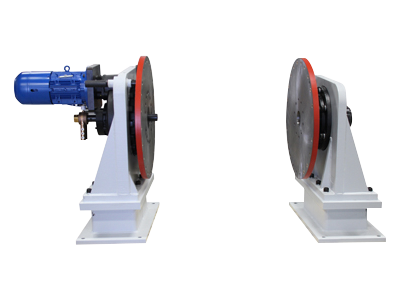

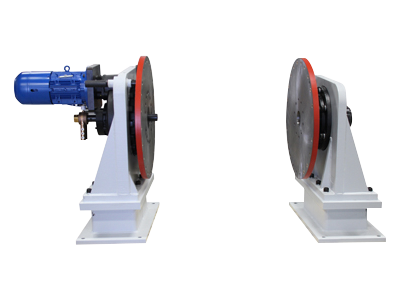

HEADSTOCK TAILSTOCK POSITIONING SYSTEM

Motion Index Drives’ TR series dual headstock tailstock trunnion positioners offer accuracy and reliability. Work with large components featuring intricate units and reduce the amount of space your equipment uses on the floor. A headstock tailstock positioning system can elevate your operations and boost efficiencies, improving your plant’s output while delivering exceptional results every time.

DUAL HEADSTOCK TAILSTOCK TRUNNION TECHNICAL BENEFITS FOR END USERS

We want to simplify your workflow by providing you with solutions that are not technically cumbersome. Take a look at some of the technical benefits:

Long service lives

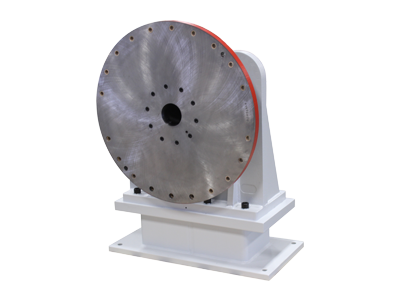

Large thru-hole on tailstock for running utilities to fixtures

Requires less power than leading competitors

Over-sized bearings on tailstock for support

Directly mount to gear head system mounting plate — eliminate the need for additional pillow blocks

HEADSTOCK TAILSTOCK BENEFITS

Our headstock tailstock positioning system has several benefits, including improved efficiency and reliability. The TR Series Trunnion Set from Motion Index Drives uses cutting-edge technology and our attention to detail to provide the most accurate solutions for your manufacturing plant. By working in unison to position complex or heavy pieces, our headstock tailstock positioners bring you precise welding with exceptional results. Our trunnion systems facilitate smooth operations through several advantages:

- Positioning, aligning and supporting components

- Providing stability of the component for increased reliability

- Adjusting accurately so you get the desired results every time

Our headstock provides precise indexing and rotation, while the tailstock delivers exceptional centering, stability and support. Get a complete solution that saves time and reduces costs.

HEADSTOCK TAILSTOCK TRUNNION POSITIONERS OPTIONS

Get solutions that fit your manufacturing plant and workflow with our options:

- Headstock and tailstock with customizable mounting plate hole patterns

- Oscillating, clockwise and counter-clockwise indexing modes

- Can be ordered as a complete assembly with a headstock tailstock positioning system and base frame

- Different gear ratios

- Customer-supplied servo motors – Motion Index Drives to mount

- Mechanical homing devices

- Safety locking devices to be used during maintenance and tooling/fixture assembly

- Variety of encoder or positioning devices

- Slip rings

- Rotary unions

Please see our RTFT and VTMF series trunnion section for higher-precision trunnion indexers and applications requiring zero backlash trunnion indexes.

HEADSTOCK AND TAILSTOCK POSITIONERS FOR IMPROVED PRODUCTIVITY

Our trunnion systems provide impeccable accuracy on your projects, allowing you to meet deadlines and accomplish more. Motion Index Drives carries custom-engineered, fully programmable indexes and robust headstock tailstock positioners that add value to your manufacturing plant and boost your productivity with fewer lag times. Determine your measurements and work with confidence, knowing you have a system designed to meet the most precise specifications.

CUSTOM-ENGINEERED TRUNNION SYSTEMS

We pride ourselves on developing the best solutions for our clients. Our team specializes in working with you to determine your application requirements so you can get a solution tailored to your plant needs. Our products are cost-effective, serviceable and customizable, providing you with a long-term investment that drives results.

Motion Index Drives provides hardened, finish-ground cam indexes that position objects accurately, making them efficient systems you can rely on. With our TR Series Headstock/Tailstock Trunnion Set, you get complete assembly to minimize downtime. Mount the gear to the head system and start working. We provide the support and technology necessary to bring you a trunnion system designed for your unique manufacturing needs.

EXPLORE YOUR OPTIONS WITH MOTION INDEX DRIVES

We know you need a trunnion system that fits your current equipment without requiring too much floor space. The TR Series Headstock/Tailstock Trunnion Set from Motion Index Drives provides superior service so you can focus on productivity while our solutions focus on completing your assignments with accuracy. See why we are the company of choice for automated equipment.

You can request more information using our online form or call us today.

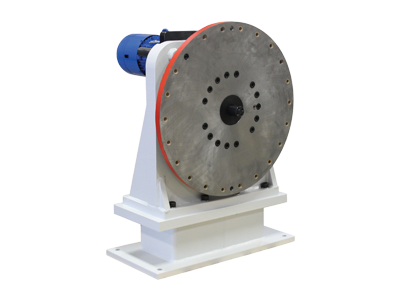

Options Available

Headstock Tailstock

Headstock

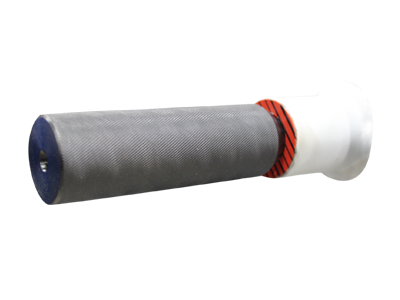

Tailstock

Grounding Mechanism

Micarta Isolation Cap

Slip Ring

Zeroing Pin