Pick and Place Units GH

Single drive for pick and place

Right angle cam for rotation

Flat cam for lift

The relationship between lift and rotation can be customized

Compact, durable unit

Optional thru-hole

Vertical Stroke up to

55 mm

Rotation up to

80º

Pendulum Angle up to

90º

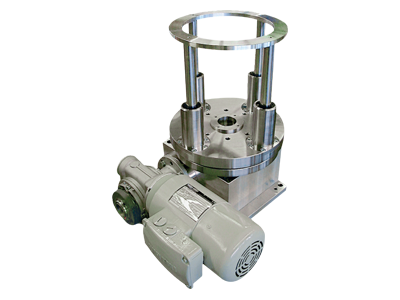

Pick and Place Units RH

Single drive for pick and place

Barrel cam for rotation

Flat cam for lift

Compact, durable unit

Optional thru-hole

Maintenance-free lubrication

Vertical Stroke up to

30 mm

Rotation up to

90º

Pendulum Angle up to

60º

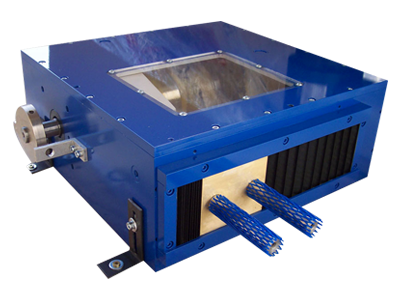

Pick and Place Units PH

Single drive for pick and place

Barrel cam for lift

Large torque with use of flat cam

Flat cam for rotation

Compact, durable unit

Optional thru-hole

Maintenance-free lubrication

Vertical Stroke up to

40 mm

Rotation up to

180°

Pendulum Angle up to

90°

Pick and Place Units RT + VT

Standard indexer for rotating

Pneumatic cylinder for lifting

Pick and placing are independently controlled from each other

Compact, durable unit

Optional thru-hole

Vertical Stroke up to

30 mm

Rotation up to

180°

Pendulum Angle up to

90°*

* Larger pendulum angle by changing the rotating direction of the drive

Pick and Place Units RT + VP

Standard indexer for rotating

Pneumatic cylinder for lifting

Lifting and rotating are independently controlled from each other

Compact, durable unit

Optional thru-hole

Vertical Stroke up to

300 mm

Rotation up to

180°

Pendulum Angle up to

90°*

*Larger pendulum angle by changing the rotating direction of the drive

Pick and Place Units HDM

Two different servo drives for lift and rotate

Vertical stroke and rotating angle are fully programmable

Customized servo drives are optional

Course of motion controlled by servo

Maintenance-free lubrication

Optional thru-hole

Vertical Stroke up to

55 mm

Rotation up to

free

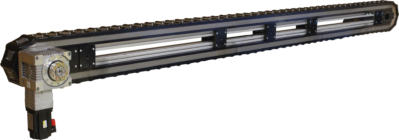

Pick and Place Units AL

Common drive for lift and rotation

Flat cam for rotation

Flat cam for lift

Vertical stroke protected by a spring

Compact, durable unit

Many available courses of motion

Multiple units can be connected using a common shaft

Vertical Stroke up to

35 mm

Horizontal stroke up to

80 mm

Motion Index Drives Pick and Place Units are customized based on the automation application requirements. Pick and place handling solutions are ideal for high-speed and high-accuracy assembly jobs. A single gear motor controls the dial table and linear lift with synchronized cams, ensuring 100% repeatability and synchronization on every index cycle. With the combination options of cylinder, disk cam, disc groove, globoid, pneumatics and servo technology results in a large variety of pick and place machine solutions.

ADVANTAGES FOR DESIGN ENGINEERS AND SPECIAL MACHINE BUILDERS

01

Oscillating index operation capabilities

02

Easy synchronization of other mechanical devices

03

Compact units offering high torque ratings

04

Many different configurations to choose

TECHNICAL BENEFITS FOR USERS

- Long service lives

- Flame-hardened cams and cam followers

- Compact designs

- Single drive operating both linear and rotary motion

- Accuracies of up to .0009″ (0.023 mm)

- Cam followers last the unit’s entire calculated life

- Completely maintenance free

- Less input power required than leading competitors

- Completely wear-free when used with optional Allen Bradley PLC Controller

OPTIONS AVAILABLE

- Reinforced output flange

- Custom lift and rotate strokes

- Custom index and dwell angles

- User-controlled stations and timing with the MOTION Flex line

- Clean room ready with MEDEX Index Drives

- Extremely high accuracy applications with NANO Indexer Technology

- More Options

CONFIGURE

YOUR NEXT PROJECT

Motion Index Drives can customize your rotary cam indexers from our standard line or an innovative new solution.