Companies are seeking cost-effective options for Robot Integrations with Rotary Indexers with a variety of robotic applications such as painting, welding, assembly, material handling and more.Rotary indexers provide manufacturers with fast and highly repeatable positions for their robots. These systems are also capable of adding a variety of assembly and inspection processes through custom components to existing systems. Custom rotary index tables can be manufactured to fit the specific robots and controls used on the production line. More importantly, to reduce cost, rotary index drives allow manufacturers to eliminate machine switchovers. This includes not having to relocate or reprogram the robot since they are all one piece—controlled by a simple open loop VFD controller and explosion proof AC motor.

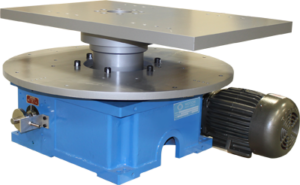

One example is a custom designed, standard RT400/4/300 rotary index drive with an integrated robot base for a spray (paint) process in an explosion-proof environment.

BENEFITS

- The input shaft is firmly connected to internal barrel cam so no additional internal torqueing is necessary

- Zero backlash is achieved with the barrel cam rotating the top dial through the cam followers

- Having the output dial mounted to a high precision four-point contact bearing assembly and pre-loaded with shims to eliminate run out.

- The seal on the RT series is designed to prevent damage from environmental conditions found in manufacturing such as dust, sand, and fluids.

Our Motion Index Drives RT series rotary indexing tables are maintenance free and have operated in various industries, sometimes running 15 years or more, without having one minute of downtime resulting from any type of equipment failure. This design and construction results in zero-backlash positioning and can be customized to any robotic system for a wide range of applications. Motion index Drives designs every product with special attention to safety, quality, versatility and value to ensure longevity and worry-free operation for many years to come.