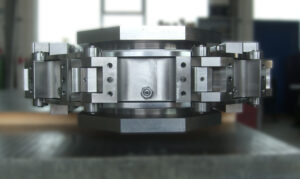

The Motion Index Drives Stainless Steel Precision Link Indexing System is manufactured to meet and exceed requirements established for “wash” down environments conducive to food processing facilities. To eliminate food borne bacteria, automation equipment endures heavy wash downs on regular basis that most of the time contain heavy corrosive chemicals that would corrode standard steel components.

These precision links were manufactured with stainless steel components in order to endure the harsh chemicals that are sprayed on it and resist corrosion from these chemicals. Corrosion of equipment can pose a threat to the safety of food products and can be extremely costly to food processing companies.

Today, a variety of foods are processed and packaged on stainless steel conveyors such as meat, fish, poultry, nuts, fruits, juice drinks and many more. The benefits of using stainless steel over alternative material for these applications is the stainless steel links ability to operate in a variety of conditions from extreme heat, humidity or cold.

Stainless steel is also the preferred choice in order to comply with the FDA regulations to use high grade materials in the manufacturing of food grade equipment. The “Corrosion-resistant” material upholds satisfactory surface cleaning features while in contact with food and the normal use of cleaning and sterilizing solutions. Because of its chemical and bacterial neutrality with food, the steel is non-threatening to consumption or taste to the food. Stainless steel adheres to requirements and conditions along with several other laws governed by the FDA states that states, “food processing equipment must be cleanable, corrosion resilient, and must have smoothly bonded seams.”

The construction of the entire Precision Link Indexing System is a key attribute to preventing bacteria. The durability and corrosion resistance of stainless steel systems is also a vital factor, enabling it to last for decades.