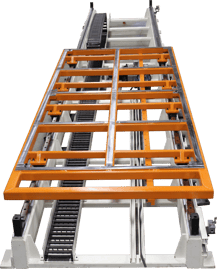

A major automotive manufacturer came to Motion Index Drives and requested that we design and manufacture a Tool Tray Shuttle that would be capable of handling very high loads and maintain a very low profile. Our shuttles are used to precisely shift tooling or parts linearly at a customer specified distances with a standard accuracy – DIN 6 on gear rack +/-0.0003”/ft. We were tasked with customizing our compact standard shuttle by providing a solution that doesn’t utilize a ballscrew or belt drive for drive method and with keeping the cable carrier within the dimensions of the tool tray itself.

Motion Index Drives designed and manufactured a Tool Tray Shuttle that utilizes a Rack and Pinion as the method of driving the movement. This Rack and Pinion is specially coated to increase hardness and reduce friction. This reduction of friction is low enough to allow this system to be lubrication free. We incorporated self-lubricating blocks for its linear rails to make the entire unit “maintenance free”. By utilizing a reduced backlash helical bevel reducer and an AC motor with an absolute encoder, the tool tray position can hold extremely tight tolerances and greater repeatability. Our Tool Tray Shuttles are engineered to have the highly flexible cable carriers that include keyed end plates so you can add or subtract based on application changes. The top is interchangeable to allow for different tooling with the controls applications that are custom set to program.

To learn more about precision link applications and selection, visit our Guide to Precision Link Indexing Conveyors and Linear Transfer Systems.

For education on Linear Transfer Units and 7th Axis Robots you can find the guide here.

View our Brochure to learn more information about our Tool Tray Transfer System.