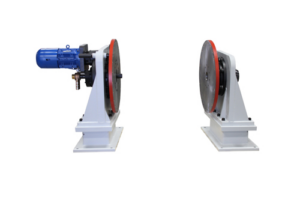

The drives for the headstock of these custom trunnions are TT251 fixed cam indexers, with a special cam profile and output follower wheel, to achieve an output rotation specific to the application.

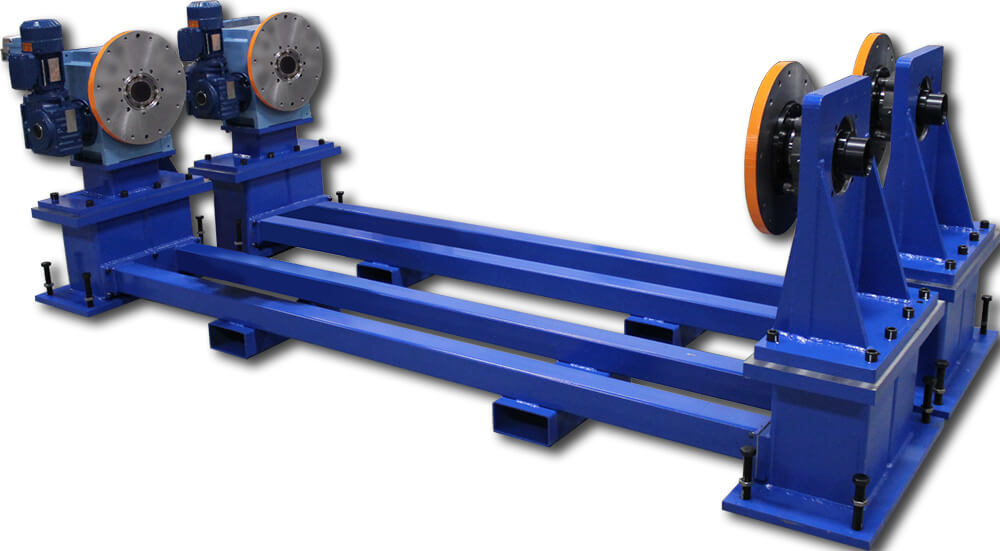

Motion Index Drives engineers and manufacturing departments are more than willing to take on the “Specials” that will allow the customer to achieve exactly what the application requires. Motion Index drives supplied the complete trunnions with the head and tail stocks, along with the complete frames for each. All the customer has to do is mount their tooling, wire up the motor and the system and customer is ready to run.

Robotic welding positioners are manufactured by Motion Index Drives and offer customers complete flexibility when determining what robot manufacture to utilize for their project. A big benefit to integrators is that our systems can adapt to any robot manufacturer their end customers are dictating to use. This minimizes design cost from project to project by not having to use a robot manufacturers dedicated auxiliary axis weld positioner for welding automation.

KEY BENEFITS

- Infinite positioning and index angle is possible

- Multiple oversized cam followers engaged in cam at all times

- Minimal maintenance

- Can utilize any motor required (AC motor with encoder, servo, etc.)

- Range in all sizes of index drives

- Capable of both high speed applications and high load

- Extremely compact relative to inertial load capability

Learn more about our single axis weld positioner , multi-axis positioning systems and headstock tailstock trunnion sets.