I often wonder sometimes when I hear customers explain about problems they have with their current suppliers. Typically, these are from end users who are dealing with a piece of equipment the machine builder has installed. The first thought that comes to mind is, “didn’t anyone ask where this equipment was going to end up”? What I have difficulty understanding or relating to is how the manufacturer of the equipment often times plays ignorant to what type of environment their equipment is going in or not knowing how it will be utilized or how the machine builder integrated the equipment. Is this from lack of training of the sales people? Is it the sales person just doesn’t care and only cares about the sale? Is it arrogance and they truly believe their equipment is the best when it really isn’t?

Recently I have come across multiple failures of a particular competitors’ units. They proudly advertise that they have had no failures in over 10 years and I find this extremely false and very misleading. Despite these failures, it is always something the customer did wrong. There is no accountability on their part.

As a supplier of a critical piece of equipment that can shut down a facility if it goes down, I know how important it is to ask the questions, not only during quoting, but after order and most importantly after the product is shipped to the machine builder. Lessons have been learned over 49 years of manufacturing. It takes a lot of time and effort to make sure equipment is applied correctly. You can not ship it and forget it and have someone dealing with major problems. How can this be avoided? By really asking relevant questions on how, what and where will this equipment be utilized. If a supplier is not asking these questions, you really have to ask yourself if you are getting the right product. If a supplier is willing to put the effort into really getting to understand the application and follow up after the sale, it should be welcomed and not avoided. Too often lately I hear manufacturers offering one or two sizes for all applications in the automotive industry, regardless of tier one, tier two or OEM. This is careless selling and adds zero value to the customer. Who typically benefits from this scenario?

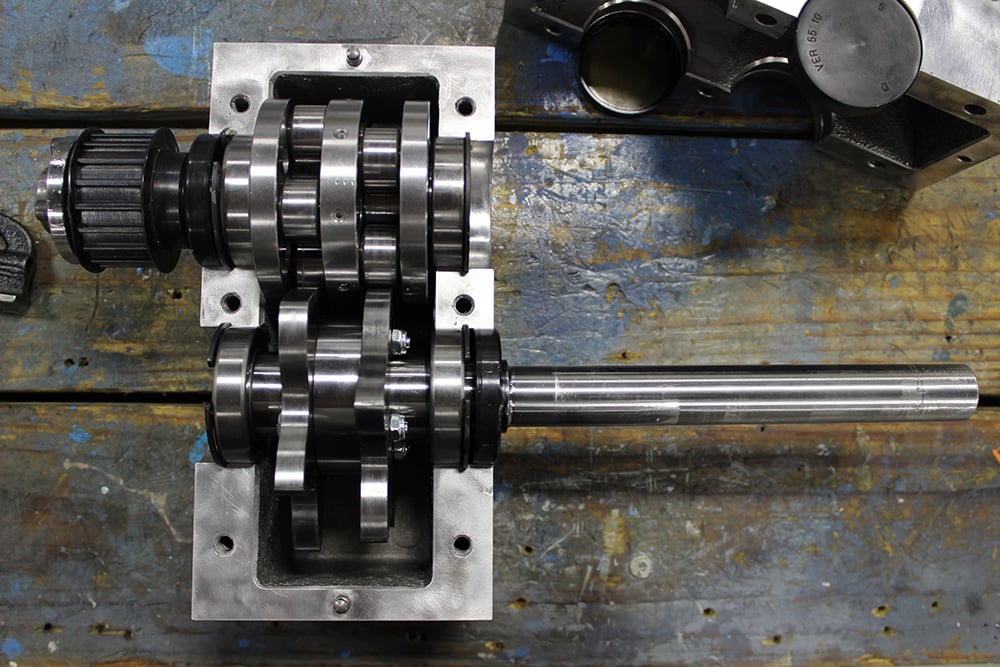

Over 49 years of supplying precision indexing equipment, we have seen all types of environments; spot welding, mig welding, laser welding, automated grinding, foundry, food processing, carbon fiber machining, nuclear energy, media blasting, and heat treating. Almost all these industries require different features to make sure the indexers operate for many years. Do Robot manufactures put standard robots in foundry applications? No, they manufacture specific type of robots for foundries. We also, provide specific style indexers, equipped with special sealing, for foundry applications. Food processing facilities, media blasting, carbon fiber machining and heat-treating applications are some of the most abusive environments for equipment. We have supplied all these with great success. Almost all of the time with these industries, you must make custom adaptations to your standard products to ensure longevity.

For questions on how we can custom manufacture our equipment to fit your application so it runs smoothly and continuously, please contact us.