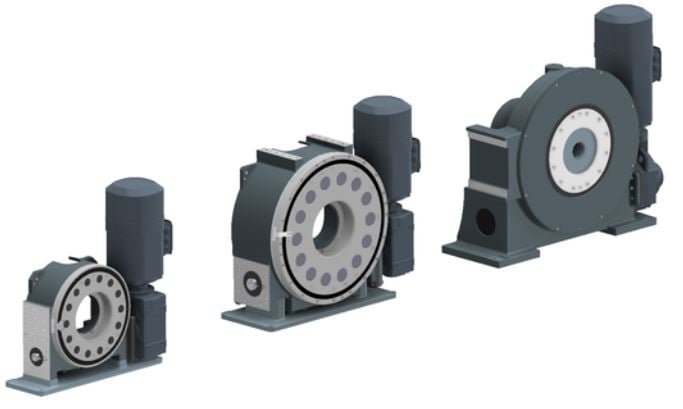

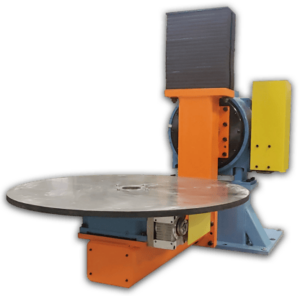

Motion Index Drives VTMF series rotary indexing tables are manufactured specifically to be used in a vertically mounted orientation. The VTMF is Motion Index Drives large series of precision rotary index tables that can be mounted as trunnions to be utilized in heavy automated robotic weld cells, robotic inspection cells or robotic assembly applications. The VTMF series is equipped with additional sealing to allow for vertical mounting. The VTMF has additional mounting surfaces machined into the housing for mounting safety lockout devices that are commonly required for vertically mounted positioning applications. Standard trunnion bases are available to easily incorporate the VTMF indexing table into a customer provided risers.

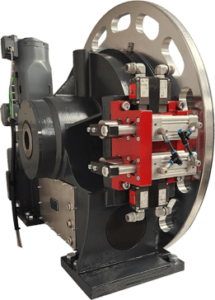

The VTMF rotary indexing tables utilizes cam and cam follower technology to provide extremely high accuracy and repeatability while offering a truly backlash free operation.

The standard VTMF1010 and VTMF2010 has a 4-point contact bearings assembly on the outer diameter of the rotating flange that provides rigidity and supports certain size loads without needing additional bearing supports. The VTMF3010 has incorporated additional bearing support to handle tremendous static torque and tilting moment for applications that cannot incorporate additional bearing support. A good example of this would be a Sky Hook weld positioning application.

The VTMF series is capable of being an aux axis to all major robot brands. A Motion Index Drives engineer can size the correct trunnion indexer and recommend the appropriate size of auxiliary axis motor that will be ideal for any application.

As far as load sizes the VTMF can handle swing diameters of approximately 2800 mm in diameter and over 2000 kg and the VTMF3010 can easily handle swing diameters of 4500 mm and several tons. As in all rotary indexing table applications there is several variables that go into sizing an indexer properly and a Motion Index Drives technician can help with sizing the right trunnion indexer for each application. Factors that will affect sizing are, mass moment of inertia, center of gravity of the total load, speed of rotation, stop time during light screen violations, what type of motor that will be used. To learn more, view our blog.