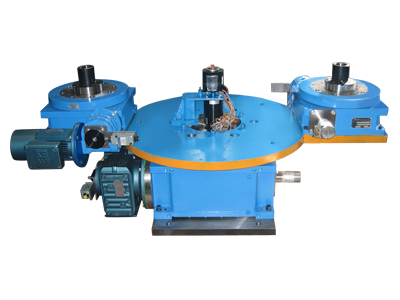

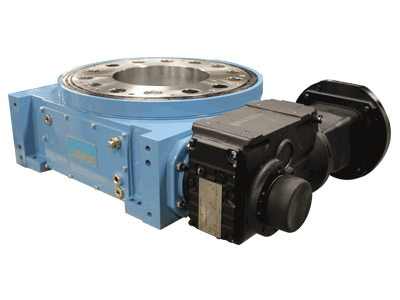

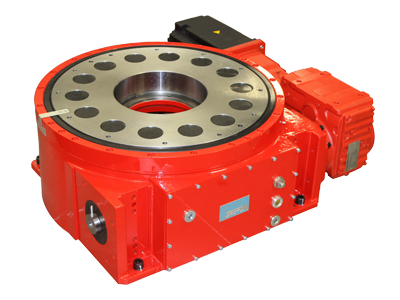

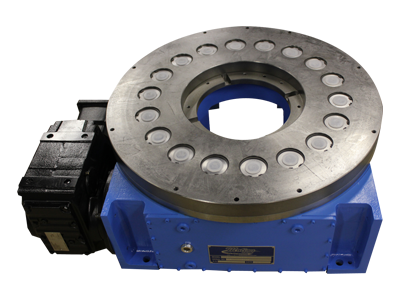

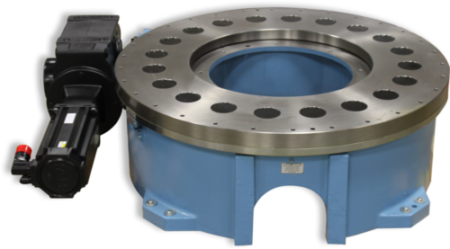

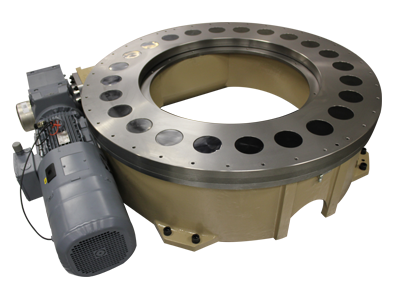

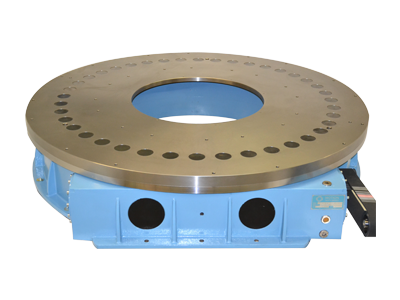

The TMF Series Programmable Rotary Index Table was engineered to satisfy the needs of the industrial manufacturing environment: fast, strong, reliable, high quality and cost effective. The TMF Series servo rotary index drive features a cast housing that is compact and has all the characteristics a manufacturer looks for: large center thru-hole for running utilities and mounting equipment. Our flexible rotary index tables are very low profile to eliminate the need for large A-frame type tooling or operator riser platforms, and a large rotating diameter for increased mounting surface.

The TMF series are our large programmable rotary index tables and are ideal for applications starting at 80 inches up to over 60 feet in diameter. The TMF Series programmable rotary table was designed to be a completely flexible rotary index table, allowing for multiple over-sized cam followers to be engaged with the barrel cam at all times. The servo rotary index drives is driven directly via a gear motor that can utilize either an AC motor with encoder, servo or auxiliary axis robot motor. All these options provide very high accuracy (less than 10 arc seconds) and allow for the flexible rotary index table to be driven via a dedicated servo drive or robot amplifier. Loading capabilities are multiplied significantly in this line of indexers through the design of the barrel cam and cam followers. This unique design allows for unprecedented inertial load capability.

TECHNICAL BENEFITS FOR USERS

Extremely reliable with long service lives

High efficiency mechanical components require less input power

Flame hardened cams and cam followers

Internal components immersed in oil bath

Low profile housing for seamless integration

Top access to cam followers

Redesigned housing for larger center thru-hole

Significantly increased strength as a result of integration of more cam followers

Inspection of internal components can be done with tooling mounted on top

ADVANTAGES FOR DESIGN ENGINEERS AND SPECIAL MACHINE BUILDERS

- Can be equipped with most major servo or robot brands

- Low profile to eliminate the need for A-frame type tooling or operator riser platforms

- Large rotating diameter for increased mounting surface

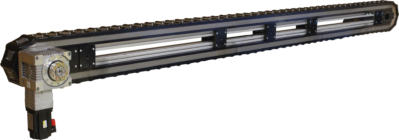

- Optional synchronization of other mechanical module

- Accuracies up to 4 arc seconds

PROGRAMMABLE ROTARY TABLE OPTIONS AVAILABLE

- Machine bases

- Robot pedestals integrated into center ring

- Custom paint and coating

- Custom dial plates or frames

- More Options

INDUSTRY EXAMPLES

- Automotive

- Industrial Machines